Lots of scans and testbeds, but not enough automation.

Test/validation providers are claiming steady progress in the race to deliver 5G network components that support millimeter-wave as well as lower-frequency networks. Going from a state of no existing off-the-shelf test equipment suitable for 5G standalone new radio (NR), test companies are introducing equipment that can handle mmWave component testing on a limited scale.

5G is a next-generation wireless communications protocol touted as revolutionary for its promise to deliver mobile network speeds with a 10X lower latency, 10X higher throughput and 3X spectrum efficiency improvement. It also will have 100X higher traffic and network capacity and efficiency to support 10X as many devices, according to John Smee, vice president of engineering at Qualcomm, in a speech at the 5G Summit during the IEEE’s recent International Microwave Symposium in Boston.

Those capabilities depend heavily on the use of advanced networking capabilities—including beamforming, phased arrays and massive multiple-input/multiple-output (mMIMO)—but they depend even more on expanding the range of frequencies available for mobile network links.

Mobile networks currently work on frequencies from 400MHz to 6GHz, focusing most in the 2.5GHz to 3.5GHz range.

Nearly all existing test and commercial 5G networks exist in the sub-6GHz range, which does require some adjustment in software, networks, antenna configuration and other functions, but only about as much change as would be required moving from 3G to 4G, for example, according to Michael Foegelle, director of technology development at ETS-Lindgren. “We’ve done that before,” he said. “It takes some effort but we know how to handle it.”

The big benefits and changes come from the shift to millimeter-wave (mmWave) frequencies above 24GHz. Those frequencies provide more bandwidth than all the other frequencies available for mobile communications combined, but they also represent unexplored territory for semiconductor makers.

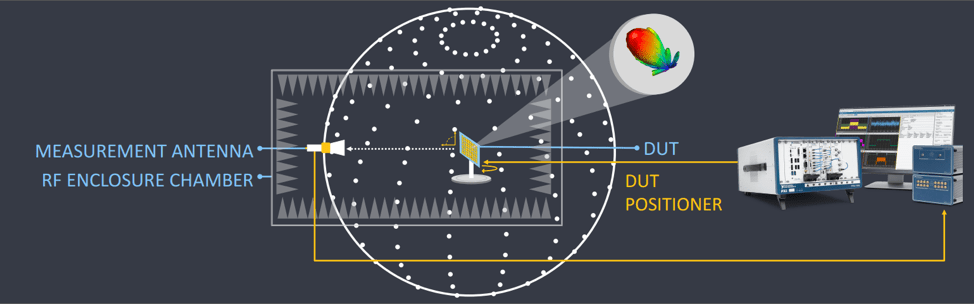

Fig. 1: Multipoint antenna testing. Source: National Instruments

“In previous generations of wireless tech, antennas were omnidirectional or wide-beam,” said Kevin Loughran, vice president and wireless CTO at Jabil, during a presentation at the recent NIWeek.

Devices designed for 5G mmWave connections require a phased-array antenna design, and that creates a problem. These antennas are too small and too complex for the power probe that was sufficient for 4G antennas. The phased-array antennas must be able to send and receive shaped waveforms tested under realistic conditions.

“5G technologies like beamforming and massive MIMO employ arrays of 64 or up to 128 antenna elements,” Loughran said. “By sending signals to multiple antenna elements and independently adjusting the phase and the gain, we can direct the energy to a particular point.”

Others see similar problems. “The key challenges are the packages and the fact that antennas may note be the actual connectors,” said Keith Schaub, vice president of U.S. Applied Research and Technology at Advantest. “With millimeter wave, the package is the antenna. Xcerra has talked about over-the-air shielded sockets over the past few years. We’re working on several things, some similar, some different. The ideal is to be able to drop it into a package and not have to touch it or test it because it’s already done. Those solutions already exist in automotive radar, but the volumes are not that large. We think we have new ideas, and we will be showcasing them in coming months. One involves how to deal with an embedded package.”

That can’t happen too soon. As recently as March of this year, experts on cell-network testing and validation said they lacked proven tools and techniques to test or validate components in new mmWave 5G devices. In fact, finding a way to test mmWave antenna/RF IC components proved to be so different from previous generations that no existing off-the-shelf test equipment was up to the challenge, a June, 2018 study published in IEEE Access.

5G antennas aren’t the first to have to be tested in an anechoic chambers, but the combination of unfamiliar antenna design, easily-blocked frequencies, incomplete standards and still-developing software make for a difficult setup with high margins of error, Foegelle said.

One of the major drawbacks for companies trying to develop their own 5G chips, components or systems is that the lack of automated test equipment (ATE)—and pressure to get 5G products out the door as fast as possible—prompted many to cobble together their own solutions using network analyzers or high-frequency RF analyzers, said David Hall, chief marketer at National Instruments.

On May 21, National Instruments announced a 5G mmWave-supporting version of its PXI Vector Signal Transceiver, a testing system for software-defined radio architectures that combines a vector signal generator, signal analyzer and FPGA-based real-time signal processor.

The unit is a PXI-based module capable of switching with 1GHz of bandwidth at frequencies to 55GHz. It can support up to 72 mmWave ports in a tester configuration, allowing integrated switching of up to 32 channels to test beamforming and phased array functions. It also allows testing at both 5Ghz to 21GHz and 23GHz to 44 GHz simultaneously.

The business end is an anechoic chamber that isolates a device under test (DUT) by suspending it within the RF-opaque chamber so that a signal source can be moved around to test it from any angle. Moving the signal source rather than the DUT helps reduce the number of moves required to test the DUT from all angles and helps reduce overall testing time, according to Gerardo Orozco, NI principal software engineer. He said measurement time was reduced from 6 minutes to about 23 seconds.

Rohde & Schwarz has developed an anechoic-chamber-based integrated testing system, as well, but it characterizes its own unit and that of NI as R&D support—a role in which fast turnaround is much lower priority than in production.

The Rohde & Schwartz unit can do either standalone testing of 5G components, or 5G integrated with 3G or 4G testing. The company had previously announced other 5G-related test equipment including a version designed for full 3GPP 5G New Radio specification testing of Qualcomm Snapdragon X50 5G modem.

Put in perspective, there has been a steady increase in 5G testing during the past year. That is now expanding include mmWave testing, as well, said Frank Schirrmeister, senior group director for product management and marketing at Cadence.

“We have seen some uptick in the last year working with the National Instrument people and with Rohde & Schwarz,” Schirrmeister said. “We have customers connecting these systems to emulation for their digital testing, but it’s less for antennas and more for their chips, which become the application processor and modem of a 5G system. Most people are using standard FPGA interfaces today, and that works on a more traditional level. But there is another whole level of testing here, as well. If you suddenly have a thousand very small devices going in to your environment, how do you test a swarm of moving objects? It would have to be done more at the simulation level, or with multi-instance emulation, to make sure those things can talk to each other. But it’s not the usual kind of testing if you’re looking more at the modem and application processor. What is interesting for us is that it looks as if our bet on emulation capacity and the ability to deal with billion-gate designs is really paying off, simply because the complexity demands it.”

Fig. 3: The challenges in test. Source: NI/IC Insights

There is definitely a lot more testing and development going on as companies rush to catch on to the 5G wave, but the need for testing and design help also comes from the complexity of the technology itself.

“If you look at Massive MIMO, the complexity is changing the baseband processor completely,” said Ron Lowman, strategic marketing manager for IoT at Synopsys. “You see ASIC designers leveraging that to build their own baseband processors and even other technologies like machine learning being added to infrastructure. High-speed SerDes are in demand to handle increasing bandwidth. The fact that there are multiple radios involved might mean more business for us, but there is also more complexity in designing the baseband for things like carrier aggregation and massive MIMO, which means more iterations, more complexity. There are so many aspects to it that it’s hard to dive into just one specific thing and just focus on that.”

As the complexity grows, the role of test equipment also changes to include more design support, which could encourage even more iterations and ore testing, Lowman noted.

The extremely high level of competition also can tempt people to make decisions based on premature assumptions about what may happen to either the mmWave or sub-6GHZ parts of the 5G market, said Rajeev Rajan, who runs global marketing, partnerships and CXO communications at ANSYS. “We seem to be pushing things a bit toward a competition right now with 5G and we don’t have the networks out yet. We have to keep our eyes on what it is supposed to do—bandwidth, low latency, high volume capacity. It’s not enough to just create something. When I was at Qualcomm they did the 4G rollout and then the optimization, and it was beautiful, but not right away. There were issues with the density of the environment in certain places, for example. Eventually we will get to a place where we have the devices and the people and the networks all moving together, and it will be like a symphony.”

How quickly that will happen isn’t clear, though. The first step is being able to test these devices quickly and sufficiently as they are moving through manufacturing, and right now that still has a long way to go.

Related Stories

Leave a Reply