Water sensors are getting smaller, lighter, cheaper, and much smarter.

Managing water resources has always been important, but that monitoring is becoming increasingly high-tech and much more useful. Rather than a spot check at the tap, or a crude measurement of water levels in a reservoir, chips are making it possible to monitor and measure water quantity and quality at the source, wherever it is stored, the spigot, and in the wastewater systems.

As climate change and unchecked population growth pressures water supplies, every drop counts. Some new sensors and networks show promise by making sensors and the networks cheaper.

The U.S. Environmental Protection Agency (EPA) sets a limit on drinking water systems in the U.S. of 90 contaminants, including both chemical and microbial. That testing must be done on schedule, although states can make more stringent rules.

The European Parliament also monitors for and limits contaminants and recently launched a watch list to monitor for two endocrine disrupting substances — beta-estradiol and nonylphenol — which can have an effect on human physiological and biochemical processes. The EU revised its drinking water standards in 2020 and made its wastewater standards more stringent.

Spurred on by these regulations, but also the need for conservation, the global water and wastewater sensors market is expected to increase by a compound annual growth rate (CAGR) of approximately 7.4% from 2021 to 2026, according to a report by Mordor Intelligence. The biggest monitoring system providers are ABB Limited, Schneider Electric SE, Honeywell International Inc., Emerson Electric Co., and Omron Corp. Over the period of the study, North America will hold the largest share of the market, but Asia-Pacific will have the highest CAGR.

“The main thing that we’re seeing is around water scarcity and water quality,” said Donna Moore, CEO and chairwoman of the LoRa Alliance. “Of all the water on the planet, 97.2% is saltwater, with only 2.8% being pure water. The problem is we’re not getting a bunch more pure water, so it’s really around water conservation and the quality of water.”

What is sensed

What can be sensed is conductivity, turbidity (the cloudiness of water from particulates), pH, salinity, temperature, dissolved oxygen, residual chlorine, ORP or oxidation-reduction potential (indicates if a body of water cleans itself), COD or chemical oxygen demand (indicates organic matter), ammonia nitrogen, chlorophyll, and blue-green algae. An ion probe sensor, which looks like a white-board marker, can find ammonia, nitrate, and chloride, among others.

Some sensors have been around for a long time. To measure flow, electromagnetic flowmeters or magmeters have been used since the 1960s. “No moving parts, low maintenance and high reliability have increased their popularity since their introduction. Not much has changed in the design, materials of construction or serviceability over the years,” writes ABB.

The magmeter, which looks like a piece of pipe and is attached inline on pipe carrying the flow, has a transmitter and a sensor that induce a voltage in conductive liquid (water). The transmitter transforms the voltage to a measurement, using Faraday’s Law of Electromagnetic Induction. Modern versions of the sensor have DSPs and connect to networks that can forward data to the applications end. Other types of flowmeters are differential pressure and ultrasonic.

But flow meters have some new twists, too. “At Infineon, we have innovative solutions using non-intrusive sensor technologies such as mmWave radar and ultrasonic sensors that can be applied to measure the flow of water,” said said Kim Lee, senior director of Applications Engineering at Infineon Technologies. “mmWave radar is also currently being used in industrial applications to measure the surface level of fluids in storage tanks. Consumer antenna-in-package radar sensors offer miniaturized sizing that can be used in smaller tanks and containers that hold our drinking water. Ultimately, Infineon strives to provide solutions that enable more energy efficient and smarter systems.”

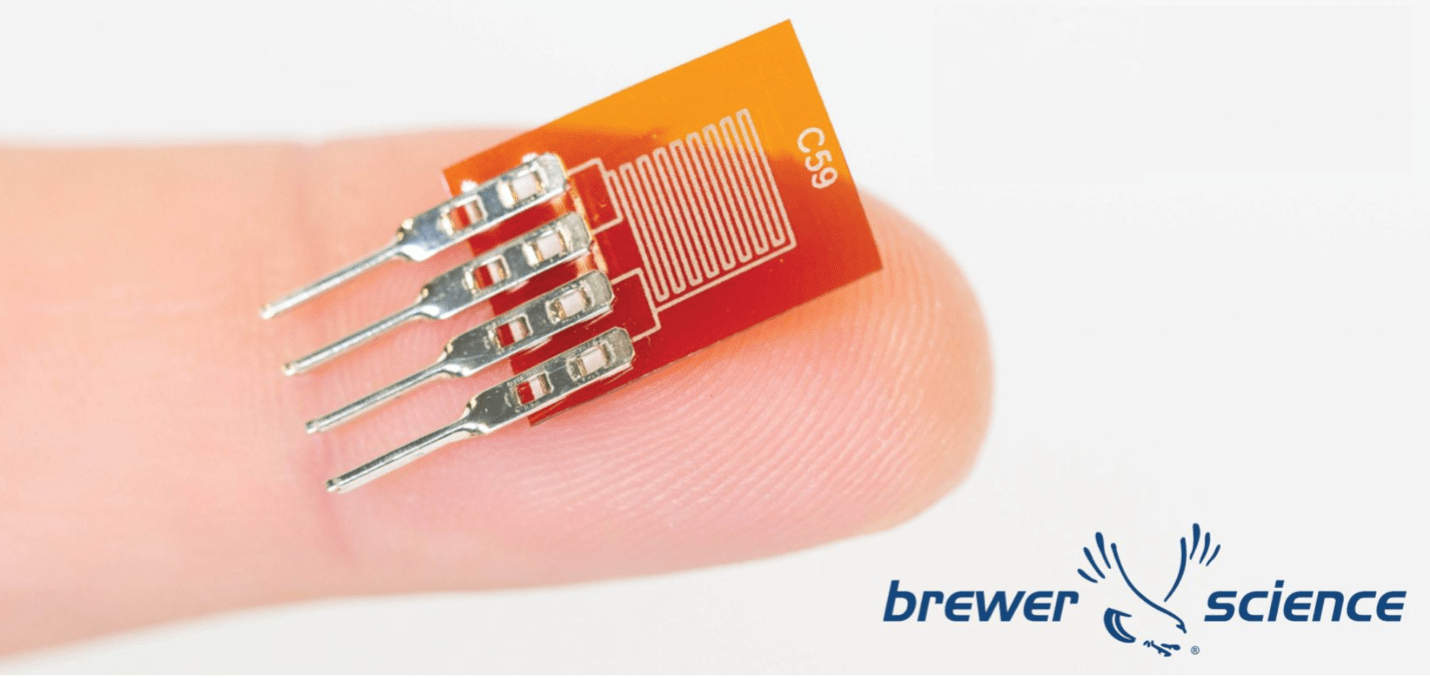

Brewer Science applied printed electronics to water sensors that measure water quality, specifically looking for contaminants such as nitrates, lead, heavy metals, and organic content, along with pH levels and ionic activity. The company started with making its own carbon nanotube-based inks, then combined that with its flexible circuit boards and printing, to make the water sensors.

“Some are CNT-based, but we also have electro-chemical based sensors and other materials we have developed over the years,” said Adam Scotch, R&D director for Smart Devices and Printed Electronics at Brewer Science, in a recent presentation. “But our focus right now is to try and use printed devices and use their small form factor and low cost of production to start distributing our sensors over large areas, so that thousands of sensors are deployed to measure the water quality of our rivers, lakes, and streams, our reservoirs, integrating it into our water treatment facilities in municipal centers, as well as measuring in distribution systems and the spigots of industrial, commercial, and residential buildings.”

Fig. 1: Brewer Science developed a printed sensor that detects lead and nitrate and can be used in real-time water monitoring. Source: Brewer Science

Getting the data

The trend is to look at the sensor systems as a whole and provide all the parts, such as sensors, network, and applications that interpret the data.

“What our customers really care about is the data. They don’t care what the sensor looks like. They don’t care how it is made. They care if the data is accurate and in as real-time as possible,” said Scotch. The goal is to build large, distributed networks of sensors, and they are currently testing them. The company developed firmware and software, including data analytics using AI and ML, for the sensor system. “We have been able to build a system that allows us to connect all of our devices and sends the data to a cloud server. There is analysis done in the cloud and then that data then gets distilled and sent to a portal or to our customers. And this is now a full system.”

Long-range low power, wide area (LPWA) networks are low-cost way that could help reduce barriers to entry. The LoRa WAN is an open long-range standard that uses LPWA network protocols over unlicensed bands, specifically the industrial, scientific, and medical (ISM) frequency bands. The LoRa Alliance is seeing a lot of use cases for water quality.

“We have a lot of projects deployments going on around water metering,” said Alper Yegin, vice president of advanced technology development at Actility, and vice-chair of the board and technical committee chair LoRa Alliance. “A lot of AMI (advanced metering infrastructure) projects are becoming a reality now with LoRa WAN because the meters are typically in extremely challenging RF conditions, such as behind closets or underground, and the high sensitivity of the LoRa WAN communication technology provides a reliable network to bring the data out of such challenging environments. Also, the battery consumption of LoRa WAN is so low that users are able to deploy meters that can go on throughout their lifetime, which is between 10 and 15 years without changing batteries.”

LoRA WAN is showing up in wastewater monitoring, especially in the industrial zones. In addition to monitoring wastewater pump stations and water quality, LoRA WAN is used in systems that give early warnings for floods, in agricultural field moisture monitoring, and in payment systems to turn off water when customers don’t pay bills (and turn it on again when they do).

The amount and frequency of data broadcast by the sensors does have an effect on the energy use, however. Getting data in real-time will be the push going forward for some of the water sensors, according to Mordor Intelligence, so whatever network and devices used would have to accommodate the constant flow of data. As more the new sensors and networks mature, real-time data flow will become a reality, where needed, and a cost savings when not needed.

Leave a Reply