Challenges and opportunities for deploying machine learning in mask making.

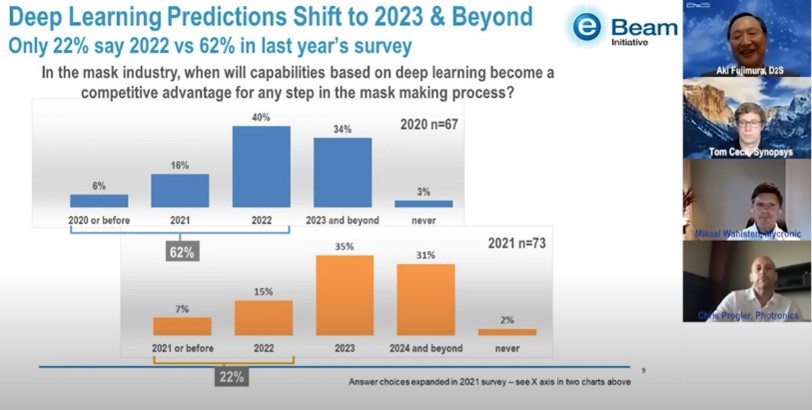

Deep learning (DL) has become an integral part of the success of many companies. There have been many papers and some reported successes in semiconductor manufacturing, yet only 22% of the luminaries participating in the 2021 eBeam Initiative Luminaries survey see DL as a competitive advantage for photomask making by next year, as shown in figure 1. Looking at that chart, the luminaries believe it will happen, but as Aki Fujimura of D2S notes in the panel, the shifting right in time means it won’t be for another 2-3 years. In this 10-minute video panel discussion moderated by Aki, three expert panelists share their experience and guidance on the right kind of projects to target for DL in the photomask making process.

Tom Cecil from Synopsys sees use cases today where DL is being deployed in optical proximity correction (OPC) and inverse lithography technology (ILT). He believes there are opportunities and runtime benefits for using DL wherever there is a high volume of image processing and modelling as part of the mask making process. Tom describes one challenge is overcoming the user’s fear of a black box they don’t understand. Aki added a contributing factor is that for mask making the answer has to be right 100% of the time.

Fig. 1: Deep learning will happen, but it’s a question of when for photomask making according to the eBeam Initiative Luminaries survey from July 2021.

Chris Progler from Photronics believes there is untapped potential with DL for photomask making but you need to start with a niche project. He describes automatic defect classification (ADC) as a big problem today that could benefit from DL because it’s highly manual, uses tons of data, and learning can continually improve. But in his experience, even that application has been difficult to implement with users due to some of the “black box” issues Tom describes.

Mikael Wahlsten from Mycronic reports that his company has moved on from the exploratory to implementation phase, but it’s taken 3-4 years of learning and finding the right projects. Mycronic is a member of the Center for Deep Learning in Electronics Manufacturing (CDLe) since 2018 along with D2S. Mikael says they’ve found many projects that are “assist” applications, which are a good place to look. He describes their first application as a support tool for service engineers to flag if there are abnormalities with the photomask writer’s output. Mikael’s advice is to look for the right projects to start, which involve monitoring and inspection but aren’t part of the “construction.”

You can watch the entire 82-minute panel video covering the additional topics of EUV photomasks, curvilinear photomasks, and deep learning here.

Leave a Reply